Sun-Proofing Your Investment In The Southwest: How to Combat UV Damage on Commercial Roofs

Imagine your commercial roof baking under the relentless 115°F sun in the middle of a Nevada summer. The surface sizzles, seams swell, and protective coatings quietly degrade under the invisible force of ultraviolet radiation. While this might sound like an extreme weather event, it’s just another day in the Southwest.

For businesses across Nevada, California, and Arizona, intense sunlight is a year-round reality. These states receive some of the highest UV exposure levels in the entire country—especially during peak summer months, when daily UV indices routinely reach “very high” or even “extreme” levels. Unlike storms or wind damage, the wear-and-tear from UV radiation is gradual and often overlooked—until it becomes a costly problem.

Whether you own a warehouse in Phoenix, manage a retail center in San Diego, or oversee a hotel in Las Vegas, your roof is your first defense against the elements. Unfortunately, it’s also one of the first parts of your building to suffer from constant sun exposure.

In this article, we’ll explore how UV rays damage various types of commercial roofing systems and—more importantly—what steps you can take to mitigate the risk, extend your roof’s lifespan, and protect your investment in the long run.

II. Understanding UV Radiation and Southwest Climate

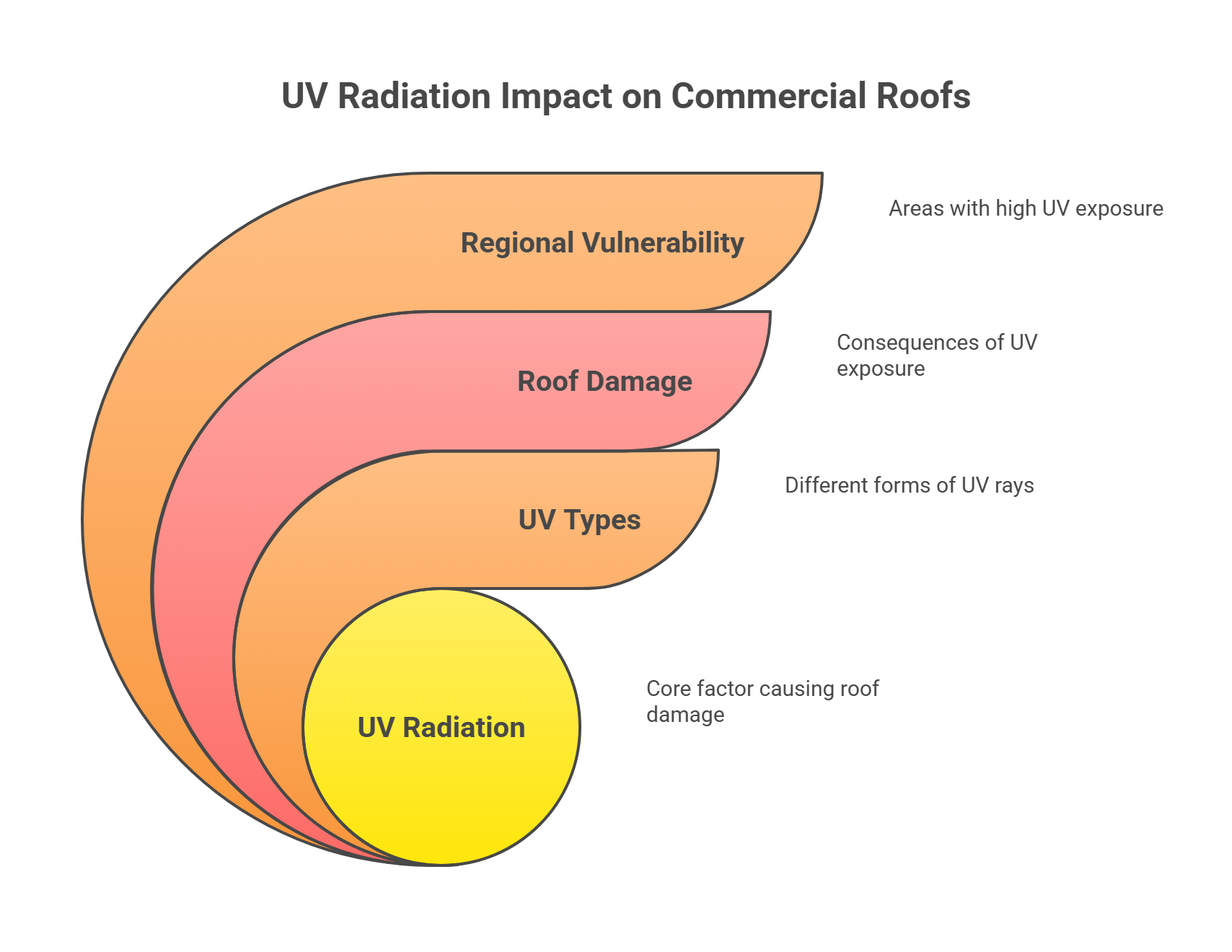

To understand how sunlight damages commercial roofs, it helps to first understand what UV radiation actually is. Ultraviolet (UV) rays are a type of electromagnetic energy emitted by the sun. They come in three main forms: UVA, which penetrates deeply and contributes to long-term material degradation; UVB, which is more intense and causes surface-level damage; and UVC, which is mostly absorbed by the Earth’s atmosphere but can be a concern in artificial light environments. Over time, the cumulative effect of UVA and UVB exposure breaks down roof membranes, sealants, and protective coatings—accelerating wear and reducing energy efficiency.

Nowhere is this more concerning than in the Southwestern United States, where sunshine dominates the forecast more than 300 days a year. Cities like Phoenix, Las Vegas, and Palm Springs regularly report some of the highest annual UV index scores in North America. This means roofs in these regions are subjected to intense, prolonged UV exposure almost every single day.

Compounding the issue, many commercial roofs in the Southwest are flat or low-slope designs, which means they absorb direct sunlight for longer periods without natural shading. This makes them especially vulnerable to UV degradation, leading to cracks, membrane fatigue, and premature aging.

III. How UV Rays Damage Commercial Roofing Systems

UV radiation is often referred to as a “silent destroyer” of commercial roofs. Unlike hail or wind, UV damage is subtle, cumulative, and often goes unnoticed—until serious issues arise. The key culprit is thermal degradation, which occurs as ultraviolet rays heat and break down roofing materials on a molecular level. This leads to cracking, brittleness, fading, and the continual expansion and contraction of materials, especially in climates with sharp day-to-night temperature swings like those in the Southwest.

Let’s break down how different roofing materials respond to prolonged UV exposure:

TPO and PVC Membranes

These white reflective membranes are designed to combat solar heat, but they’re not immune to UV deterioration. Over time, UV rays can cause surface chalking, where the top layer begins to powder and degrade. Heat-welded seams may weaken, increasing the risk of splits and leaks, especially if the membrane is aging or poorly maintained.

EPDM Rubber Roofing

EPDM is known for its flexibility and weather resistance, but UV rays cause it to lose elasticity over time. The surface may become brittle, crack, or shrink, particularly at the edges and seams. Shrinkage can pull the membrane away from flashing or drains, leading to water infiltration.

Built-Up Roofing (BUR) Systems

BUR systems rely on layers of asphalt and felt with a protective top coat, often gravel or mineral-surfaced cap sheets. UV rays can degrade the top layer, exposing the underlying plies. As exposure continues, the inner layers become brittle and start to delaminate, leading to widespread system failure if left untreated.

Metal Roofing

While metal roofs are durable and often reflective, UV exposure can still take a toll. Prolonged sunlight causes thermal cycling—the constant expansion and contraction of metal panels—which weakens seams, fasteners, and panel coatings. Over time, UV radiation can fade or chalk factory-applied finishes, reducing both aesthetic appeal and corrosion resistance.

System-Wide Consequences

In all roofing types, UV damage leads to the loss of waterproofing integrity. Once sealants and membranes begin to crack, water infiltration becomes inevitable. Additionally, energy efficiency drops, as damaged or darkened surfaces absorb more heat, forcing HVAC systems to work harder and increasing cooling costs.

IV. Warning Signs of UV-Related Roof Damage

Because UV degradation happens gradually, it’s easy for property owners and facility managers to overlook the early signs—until the damage is advanced and expensive to fix. However, knowing what to look for can help you catch problems early and take corrective action before major issues develop.

Here are the most common visible and performance-related indicators of UV damage on commercial roofs:

1. Blistering and Surface Chalking

UV radiation often causes blistering—small bubbles or raised areas on the roof surface—indicating trapped moisture or membrane separation. In TPO and PVC roofs, chalking appears as a white, powdery residue that signals surface layer degradation.

2. Cracking and Splitting at Seams

As roofing materials become brittle from prolonged UV exposure, you may notice hairline cracks or more severe splits along seams, corners, or flashings. These can rapidly expand with daily thermal cycling and eventually compromise the waterproof barrier.

3. Discoloration or Fading

Faded or uneven roof coloration—especially in areas exposed to direct sunlight—is a telltale sign of UV oxidation. While it may seem cosmetic, discoloration often signals a loss of protective coating, which accelerates further damage.

4. Granule Loss (on Modified Bitumen and BUR Systems)

Granules protect asphalt-based roofs from UV rays. If you notice bare patches or excessive granule runoff in drains and gutters, the top protective layer has likely worn away, leaving the system vulnerable to accelerated decay.

5. Warping or Membrane Shrinkage

In rubber and polymer-based systems like EPDM, prolonged exposure can cause membranes to contract and pull away from roof edges or protrusions. This exposes seams, fasteners, and penetrations to water intrusion.

6. Rising Energy Bills

An often-overlooked indicator of UV damage is an unexpected spike in cooling costs. As roof surfaces degrade and become darker or less reflective, they retain more heat—forcing your building’s HVAC system to work harder to maintain comfortable interior temperatures.

By recognizing these early red flags and scheduling timely roof inspections, building owners in the Southwest can avoid costly structural repairs and extend the service life of their commercial roofs.

V. Long-Term Costs of Ignoring UV Damage

Ignoring the slow but steady toll of UV damage on your commercial roof can lead to significant long-term costs—many of which escalate silently until they demand urgent attention.

1. Shortened Roof Lifespan

Even a high-quality commercial roof rated for 20–30 years can fail prematurely—sometimes in as little as 10–15 years—if exposed to unmitigated UV radiation. Once the surface layer breaks down, the underlying structure deteriorates rapidly.

2. Increased Energy Costs

As roofing materials fade, crack, or lose their reflective coatings, they begin to absorb rather than deflect solar energy. This raises rooftop temperatures and forces HVAC systems to work harder, increasing your utility bills month after month.

3. Risk of Leaks and Structural Water Damage

UV-damaged seams and membranes are far more likely to fail under rain, especially during monsoon or storm events. Water infiltration can lead to interior ceiling stains, mold growth, and even electrical hazards—all of which are costly to remediate.

4. Insurance and Warranty Complications

Many warranties and insurance policies exclude coverage for neglect or lack of maintenance. If damage is traced back to UV exposure that could have been prevented through routine care, your claim may be denied entirely.

5. Expensive Roof Replacement

If damage goes unchecked, full replacement becomes the only option. In the Southwest, commercial roof replacements typically cost between $8–$20 per square foot, translating to tens (or hundreds) of thousands of dollars depending on roof size and complexity.

In short, UV neglect isn’t just a maintenance issue—it’s a financial liability that can quietly erode your bottom line.

VI. Proven Mitigation Strategies

The good news is that UV damage—while inevitable in sun-drenched climates like the Southwest—can be significantly slowed or even prevented with proactive planning and modern roofing technologies. Here are five proven strategies that help commercial property owners defend their roofs against solar degradation and extend the lifespan of their investment.

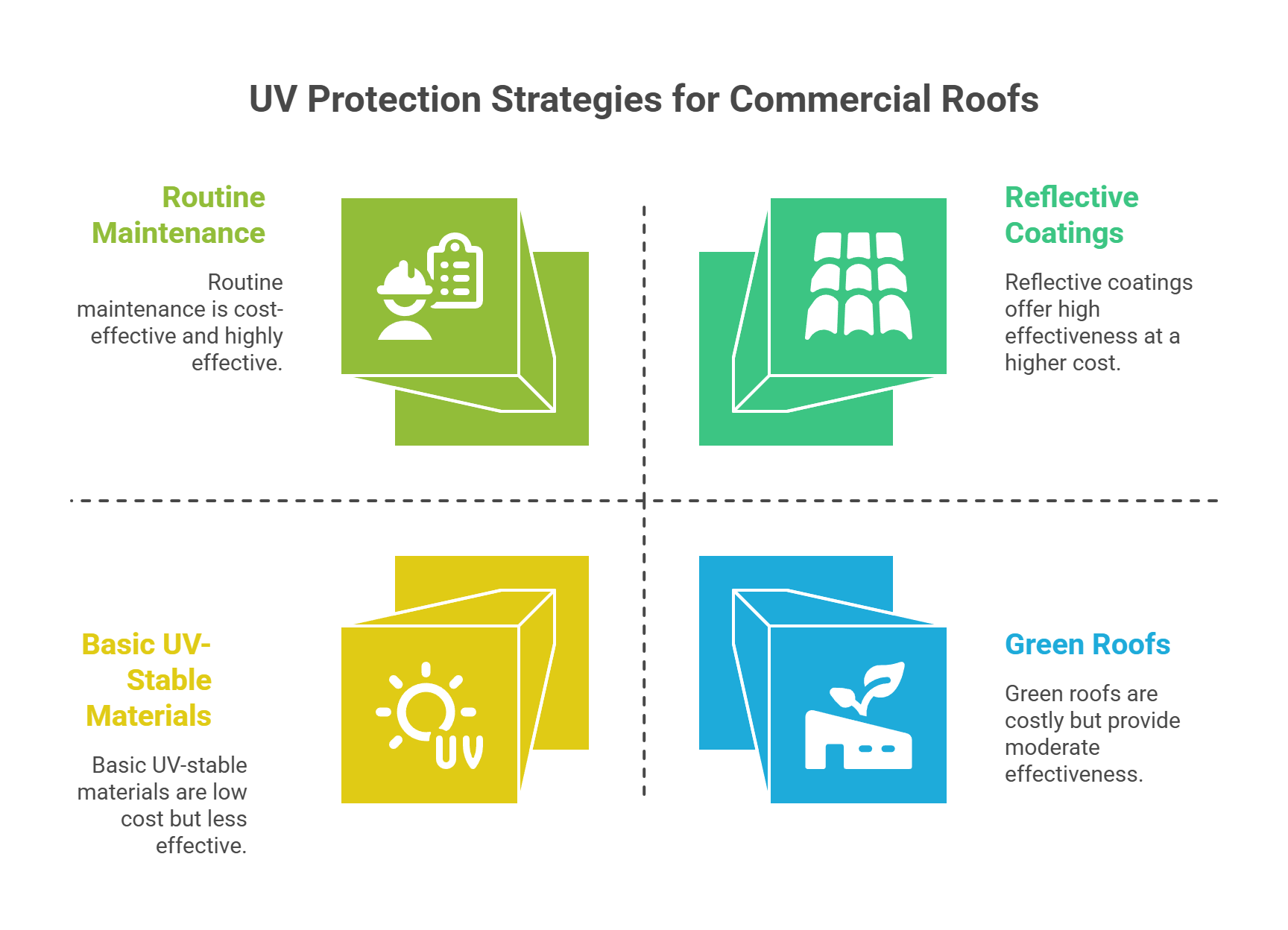

1. Reflective Coatings & Cool Roof Solutions

One of the most effective and affordable defenses against UV rays is applying reflective roof coatings, such as acrylic, silicone, or elastomeric products. These coatings form a durable membrane that bounces back much of the sun’s energy rather than absorbing it.

Benefits include:

- Reduced rooftop surface temperatures (often by 20–50°F)

- Extended life of the base roofing material

- Improved building energy efficiency

- Potential eligibility for local or utility rebates under cool roof programs

2. Use of UV-Stable Roofing Materials

When installing a new roof or replacing an aging one, it’s critical to choose materials engineered for high UV exposure:

- TPO (Thermoplastic Olefin): Naturally reflective and heat-resistant, especially in white or light-colored variants.

- White EPDM: Offers cooler surface temperatures compared to traditional black rubber membranes.

- Metal Roofing with Reflective Finishes: Pre-painted or powder-coated metals can maintain solar reflectivity for years.

- SPF (Spray Polyurethane Foam): When properly coated and maintained on a 10–15 year cycle, SPF roofs offer excellent UV and thermal protection.

These materials are particularly well-suited for flat or low-slope roofs, which absorb more sunlight due to their orientation.

3. Roof Maintenance and Inspection Schedules

Routine maintenance is your frontline defense against UV damage. Experts recommend bi-annual roof inspections, ideally before and after the harsh summer season. These inspections should include:

- Visual checks for cracks, bubbling, or discoloration

- Thermal imaging scans to detect hidden moisture or heat absorption zones

- Drone surveys for larger or difficult-to-access roofs

Regular inspections allow for early detection and cost-effective repairs, keeping minor issues from turning into major replacements.

4. Green Roofs and Ballast Systems

For buildings in urban environments, green roofs—which use soil and vegetation layers—act as natural UV shields while providing insulation and stormwater management. Alternatively, ballasted roofing systems use gravel or pavers to protect underlying membranes from direct sunlight.

These approaches are ideal for large structures with load-bearing capacity and help reduce the urban heat island effect.

5. Strategic Roof Design Elements

Architectural design can also play a role in UV protection. Consider:

- Shading structures or rooftop pergolas

- Parapet walls or overhangs to shield membrane edges

- Solar panel installations, which not only produce energy but also cast shade, acting as dual-purpose UV blockers

Each of these elements reduces UV exposure and adds functional or aesthetic value to your property.

VII. Regional Roofing Case Studies

To put these strategies into real-world context, here are two case studies from the Southwest that show how smart roofing decisions can lead to significant cost savings and performance improvements under harsh UV conditions.

Case Study 1: Phoenix Warehouse Applies Silicone Coating and Cuts Cooling Costs

A 50,000-square-foot distribution warehouse in Phoenix, Arizona struggled with escalating energy bills during the summer months. The original black rubber roof absorbed excessive heat, causing the building’s HVAC system to run continuously. In 2021, the property manager applied a white silicone reflective coating across the entire roof surface.

Results:

- Surface temperatures dropped by nearly 40°F during peak sunlight hours

- Interior cooling demand decreased significantly

- The facility reported a 20% reduction in cooling-related energy costs within the first year

- The roof’s projected lifespan was extended by 10 years, deferring costly replacement

Case Study 2: Las Vegas Retail Strip Preserves Roof With Scheduled SPF Recoating

In Las Vegas, Nevada, a retail strip mall with a spray polyurethane foam (SPF) roof faced premature UV damage due to missed maintenance cycles. A new management team implemented a routine 10-year recoating schedule using UV-resistant topcoats.

Results:

- No major repairs required over a 15-year period

- Maintained high reflectivity and waterproofing performance

- Avoided full roof replacement, saving over $150,000 in projected costs

These examples show how proactive UV mitigation can translate directly into operational savings and extended asset life, especially in high-sun regions like the Southwest.

VIII. Choosing the Right Roofing Partner

Implementing UV protection strategies is only as effective as the team behind them. That’s why choosing the right commercial roofing partner is critical—especially in high-UV regions like Nevada, California, and Arizona.

Look for a roofing contractor with deep experience in Southwest climates and a track record of successful UV mitigation projects. They should be familiar with reflective coatings, advanced roofing materials, and long-term maintenance planning specific to sun-intensive environments.

Here are a few key qualifications to prioritize:

- Licensing and insurance for commercial roofing work in your state

- Proven expertise with UV-resistant systems like TPO, white EPDM, and metal

- Ability to offer thermal imaging and drone inspection services

- A strong portfolio of past projects with measurable energy savings

- Manufacturer-certified installer status, ensuring your warranty remains valid

Also, ask whether they offer roof management programs, which include scheduled inspections, documentation, and lifecycle planning. This proactive approach often helps building owners qualify for insurance benefits and utility rebates—while extending the useful life of their roofing system.

Your roof is a capital asset—partnering with the right experts ensures it performs like one.

IX. Final Takeaways and Call to Action

The Southwest’s climate—blazing sun, high UV indices, and extreme rooftop temperatures—is a serious test for any commercial roofing system. And while UV damage often occurs silently, its consequences are anything but subtle: cracking membranes, energy-draining heat retention, leaks, and costly replacements.

But this is a solvable problem.

By understanding how UV rays degrade different roofing materials, recognizing early warning signs, and implementing proven mitigation strategies—such as reflective coatings, UV-stable materials, and proactive maintenance—you can extend your roof’s lifespan, lower operational costs, and protect your building from long-term structural damage.

Most importantly, don’t wait for visible damage to appear. UV degradation begins long before the first leak.

Take the first step today:

Schedule a free commercial roof inspection with a trusted Southwest roofing expert.

Whether you manage a warehouse in Phoenix, an office park in San Diego, or a retail center in Las Vegas, we’ll help you build a roof management plan that’s tailored for intense sun exposure—so your roof stays strong, cool, and leak-free for years to come.